A gas strut, also known as a gas spring or gas shock, is an essential component in various mechanical systems, offering controlled motion and support. From automotive engineering to furniture manufacturing, these devices play a crucial role in countless applications. In this article, we delve deep into the world of gas struts, exploring their functions, benefits, maintenance tips, and much more.

What is a gas strut?

Definition and function

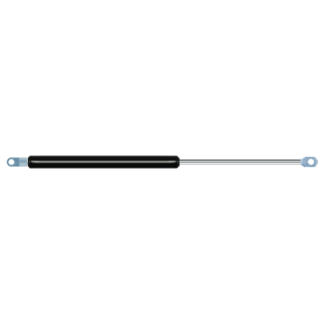

A gas strut is a mechanical device designed to provide controlled motion and support in various applications. Gas struts consist of a piston rod, cylinder, and pressurized gas, typically nitrogen, enclosed within a sealed chamber. The primary function of a gas strut is to exert force to support, lift, or dampen motion in a wide range of equipment and machinery.

Anatomy and working principle

Gas struts operate on the principle of compressed gas stored within a cylinder. When pressure is applied to the piston rod, the gas compresses, creating resistance. This resistance generates a force that can be used to lift or support loads. The sealed chamber prevents the escape of gas, ensuring consistent performance over time.

What types of gas struts are available?

Compression gas struts

Compression gas struts are the most common type, typically used for lifting and supporting applications. They exert force in the direction of compression, making them ideal for tasks such as opening and closing doors, hatches, and lids.

Tension gas struts

Tension gas struts operate in the opposite manner, exerting force in the direction of extension. They are often employed in applications where a pulling force is required, such as in canopy supports and adjustable furniture.

Lockable gas struts

Lockable gas struts feature a mechanism that allows users to lock the strut in a specific position. This feature is useful for applications requiring precise control over the extension or compression of the strut, such as medical equipment and ergonomic furniture.

Stainless steel gas struts

Stainless steel gas struts are designed for environments where corrosion resistance is paramount, such as marine and outdoor applications. They offer the same functionality as standard gas struts but with added durability in harsh conditions.

Applications of a gas strut

Automotive

Gas struts play a vital role in automotive engineering, where they are used in bonnet and tailgate systems, boot lids, and convertible roofs. They provide smooth and reliable operation, enhancing the user experience and safety of vehicles.

Furniture

In the furniture industry, gas struts are commonly employed in recliners, office chairs, and storage beds. They enable effortless adjustment of seat positions and facilitate smooth opening and closing of storage compartments.

Industrial machinery

Gas struts are indispensable in industrial machinery, where they assist in lifting heavy loads, adjusting equipment height, and damping vibrations. Their compact design and adjustable force make them ideal for a wide range of applications, from assembly lines to heavy-duty machinery.

Aerospace

In the aerospace sector, gas struts are utilized in aircraft doors, cargo compartments, and seating systems. Their lightweight construction, precise control, and reliability are essential for ensuring safe and efficient operation in demanding aerospace environments.

What are the advantages of gas struts?

Smooth operation

A gas strut offers smooth and controlled motion, providing users with a comfortable and effortless experience. Whether opening a car boot or adjusting a seat, gas struts ensure fluid movement without jolts or jerks.

Adjustable force

One of the key benefits of a gas strut is the adjustable force capability. By varying the pressure of the compressed gas, users can tailor the strut’s performance to suit specific applications, ensuring optimal support and safety.

Space efficiency

Gas struts are compact and space-efficient, making them ideal for applications where size and weight are critical factors. Their lightweight design and high force-to-weight ratio maximize available space and minimize installation footprint.

Durability and reliability

Constructed from high-quality materials and engineered for precision, a gas strut is known for its durability and reliability. With proper maintenance and care, they can withstand years of continuous use without compromising performance.

Maintenance tips

Regular inspection

To ensure optimal performance and safety, a gas strut should be inspected regularly for signs of wear, damage, or leakage. Visual inspection of the cylinder, piston rod, and seals can help identify potential issues early on.

Cleaning and lubrication

Keeping your gas strut clean and properly lubricated is essential for maintaining smooth operation and prolonging service life. Use a mild detergent and water to clean the exterior surfaces, and apply a silicone-based lubricant to the seals and moving parts.

Replacement schedule

Despite their durability, gas struts will eventually wear out and require replacement. Establishing a regular replacement schedule based on usage and environmental conditions can help prevent unexpected failures and ensure uninterrupted operation.

Choosing the right gas strut

We would like to simplify the often complex process of ordering gas struts for a variety of applications. We assure a seamless shopping experience with the help of our online tools, designed to assist you in choosing the best option for your specific task.

-

- Calculator tool

What type of gas strut do you need? Determining the correct size and strength can be challenging. This is where our calculator tool comes in. Simply input parameters such as length, width, weight, pivot point, angles, and more, and the tool will guide you, recommending the best gas powered struts for you. - Replacement tool

Over time, your once-efficient gas strut may lose its effectiveness. For situations where safety is crucial, prompt gas spring replacement is essential. Our replacement tool simplifies this process, helping you quickly identify equivalent replacements for popular gas strut brands. Enter the product number, select the recommended product, verify, and order with ease. Begin your search for the ideal gas struts with our replacement tool. - Configurator tool

For those who enjoy customization, the configurator tool is the best solution. Its interactive platform allows you to choose materials, switch between measurement units, and select mounting options and gas spring types. You can even preview a 3D model. Afterward, specify the necessary force in Newtons (calculated via the calculator tool). Once completed, add your custom gas strut to your cart and proceed to checkout.

- Calculator tool

Order your gas struts at Gasspringsshop

Now you know what a gas strut is! Order your gas struts online at gasspringsshop.co.uk. Any questions? Our support team is always ready to assist. Contact us via email at [email protected] or call us at +44(0)24 7645 5580.