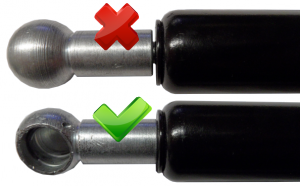

- Make sure there is sufficient play in the cylinder hook-ups, i.e. avoid rigid installation. If required, lubricate cylinder end fitting in order to achieve lower friction forces and an increased life time of the fittings.

- Make sure the piston rod does not get jammed (for long strokes/products, an additional bearing/guide must be provided for the product; sagging, bending or kinking must be avoided).

- Only axial loads are permissible (risk of bending!). Cross or torsion forces must not occur.

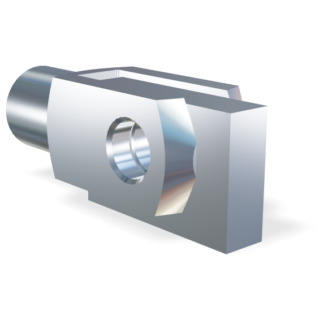

- Screwed-on fittings (eylet etc.) must be screwed in completely and rest firmly on the face if required. Possibly loose fittings must be screwed on completely prior to installation. Should vibrations occur, the fittings must be secured against twisting (by gluing in).

Our configurator shows all measurements of gas springs. If you are looking for a replacement gas spring, you can try to find a suitable one with the configurator.